↓

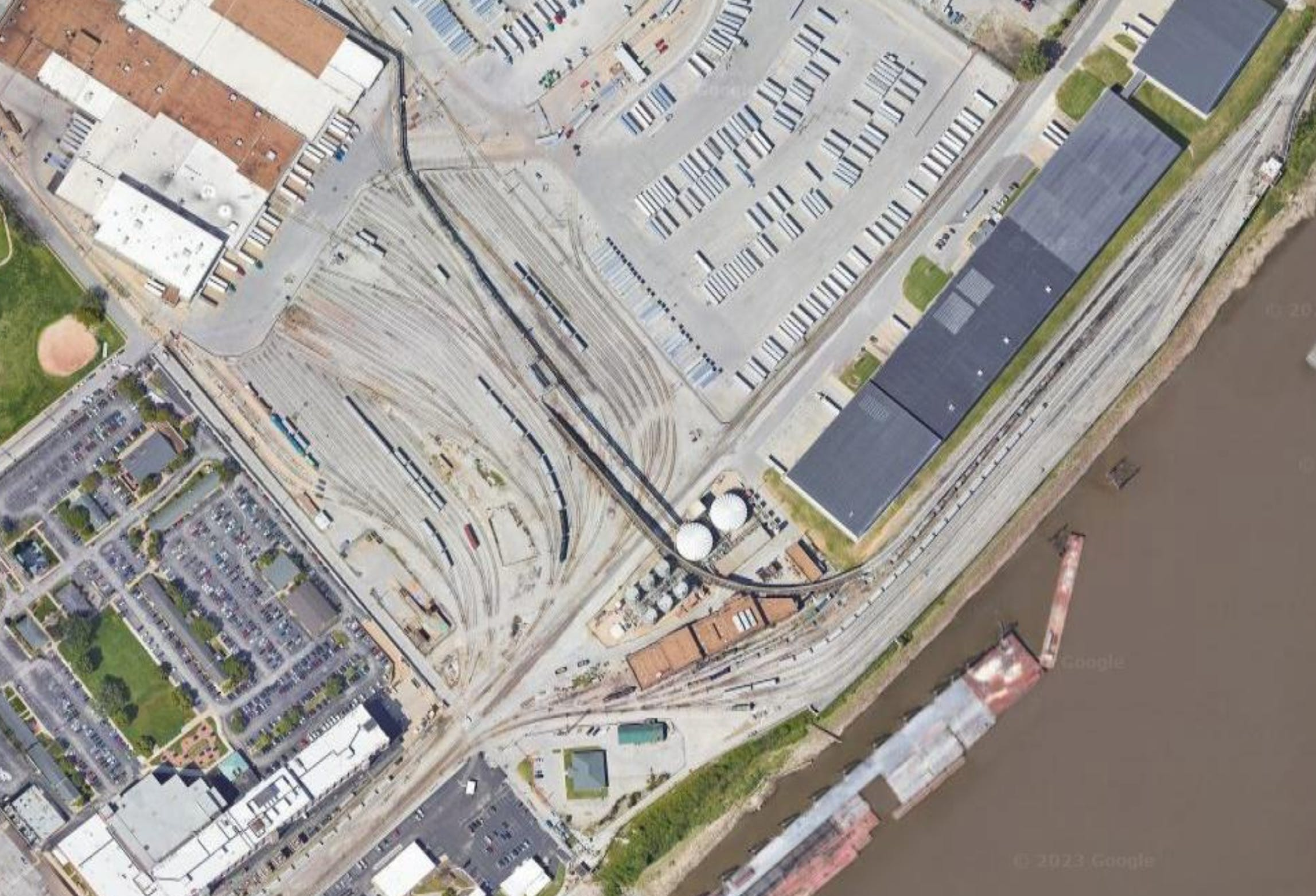

"And this is where everything leaves."

Billy, the Regional Transportation Manager for the world's largest beer company, gestured out the bay windows towards an array of a dozen rail line terminals, scores of 53-foot trucks actively cycling, and a handful of barges docking along the banks of the Mississippi River just one thousand feet to the southeast.

The network in my grey matter was equally busy, and concerned. It was late 2014, and my first startup's success now depended on selling software into a world of workflows dictated by distance, time, and space: foreign concepts to a SaaS with flexible hours and a product saved to bytes before being shipped to a metaphorical cloud.

Come Not As You Are

It's unfortunate that one of the things we all appear to have gotten out of our real or imagined product strategy class was the importance of differentiation.

In many ways, being different makes things worse. If I'm hiring you to do a thing, that thing is familiar to me. The shape of the hole I'm looking to fill is familiar to me. The outcome I'm seeking is well known, maybe even established through a goal or target.

I just want that 80,000 pounds of beer shipped safely: can you help me do that?

That's all Jenn wanted to know.

Jenn worked for Billy, and Jenn did not want different. Of course, she never said so, at least not in that way, but deep down, and when we weren't looking, the last thing she wanted to do was log in to our software and do things differently than she had for the last 20 years.

This was awkward.

Fading Into You

Bob Moesta tackles this head-on in his excellent Demand-Side Sales, which includes a set of interviews that take so long to get to the things product people want to talk about (solutions, differentiation) it's painful.

It's almost like you have to have this whole conversation first, where you ask a lot of questions, and they say a lot of stuff about themselves, before you even get a chance to tell them about what makes you so special!

I really thought I had done that with Jenn. She attended the meetings, the relationship-building baseball game, the conference calls. But the usage analytics told a different story.

She had logged in once in six months. "I tried it!" she told her boss.

Jenn was the villain of our story — the laggard that didn't want change. But she also represented an inescapable truth: the way we created value was allowed to be different, but the way we delivered that value had to be the same.

As what?

Suddenly I Can See Everything Wrong With Me

In software, we're forced to delineate responsibilities and sections of code with things like function calls, API's, and interfaces. These are the places where A passes x, y, z to B. Now B does something with it and sends it back or passes it elsewhere.

It's so clear! (Sometimes.)

In sales, your prospect's work and life also run on a set of contracts and interfaces. Yes, they're fuzzy and largely undocumented, but their world is composed of a series of a series of steps (not a typo) they take to accomplish the thing: making coffee, shipping beer.

Oh I get it! How quaint! Making coffee is makeCoffee(x). Shipping beer is shipBeer(x).

No. There is no makeCoffee(x).

There is only (and this is simple):

addCream(brew(grind(scoop(x)), addWater())).

If it were as simple as makeCoffee(x), it wouldn't be a $495B industry.

Cut Along the Dotted Lines

We got in trouble and made things worse for Jenn when we failed to decompose her world enough to honor her existing contracts and interfaces.

We thought we were just asking her to "update her workflow". In truth, we were asking her to refactor her entire code base and change the contracts she had established with the surrounding workflows.

We ended up winning her, and the 2015 contract renewal, by painstakingly mapping the steps she took each morning to produce her work product, and then matching the input and output of our product to those agreements she had made with the prior and subsequent steps of her routine.

Of course, the way our product processed that input and generated that output were whizz bang better than her existing tool.

But she didn't care about any of that. She just needed us to choose a dotted line, cut along it cleanly, and leave the rest alone.

To find fit, we had to keep our differentiation contained.